I know what you’re thinking. Seriously, I do. And I’ll prove it. I’ll prove it with a statement:

all measurements are precluded by a conceptualization.

If that sounds somewhat elaborate, let me explain. If I say the word “window” to you, an automatic thought process will begin in your mind. As soon as you heard me say ‘window’ you started without realizing it to measure a window. First, you connected the word to what you know to be what a window is (a frame with a plane of glass, designed to see through or to let light in) and then you gave this suggested window a shape (rectangular). Next, consciously or not, you assumed an approximate size (let’s say a typical 1 m X 1.2 m).

In short, you matched the word I spoke to the concept of a ‘window’ as you know a window to be in your experience. The fact that you did this isn’t unusual. We do the same sort of conceptualizing all the time. In fact, everything we see is matched to our accumulated knowledge and experience and when the parameter held in our mental concept library matches the actual image, no further thought is given to the matter.

See. I knew what you were thinking. At least I did when I said the word “window”.

Conceptualizing?

Now, let’s take that thought and dig deeper. If you think about it, we walk around all day, every day seeing shapes and measurements. But what happens if we see an object we don’t instantly recognize and know how to classify – something unfamiliar or unusual?

Then, the first thing that happens is that we assess its shape and relative size. Is it round? Square? Quadratic? Big? Small? Then, our conscious mind now alerted to this unknown, we also start to determine more complex issues. Is the object dangerous to me? Does it resemble something like another object I know? There’s a point to my venture into what appears to be cod psychology here. That is, we always try to assess things by fitting then into familiar patterns.

If you’re wondering what my point here is, let me explain. The process I’ve just described isn’t just an exercise in psychology; it’s relevant because it’s also the basis of all measurement technology. Why so? Because we cannot measure something without knowing what we are measuring.

Is it a cross-section? A diameter? A diagonal? Unless we know this, the measurement result we attain from trying to measure something will be of no use. For instance, before we can measure a diameter, we must first assess the object as being round. (You might think ‘circular’ was the correct term here, but as we shall see, a circle is rarely a perfect circle in the physical world. Hence use of the less well-defined term ‘round’.) Rectangular objects require other measurements to round ones, triangles yet others, and so on.

In the world of measurement, what’s going on here is that you’re defining a model before deciding what measurement to take. And this model is further defined by a set of parameters which define several features that can be measured in specific ways.

In practice

With me? Let’s summarize. We’ve so far established that we always create, implicitly or explicitly, a model before measuring something. Presented with an object, our brain will automatically compare it to a ‘library’ of known shapes and objects. Once that’s done, we know the parameters for measuring it. Model-Based Measurement works the same way. It requires an initial choice of shape to be made.

Therefore, in practice, before an actual measurement is taken, a nominal model must be loaded into the measurement device (just as it is in our head). If the nominal model is round, we expect to be able to measure diameter. This nominal model is a description of what we anticipate being able to find when the measurement is done. With it in hand, the actual recording of the measurement is made in anticipation that the object being measured will match the model being used for measuring.

Enter, the nominal model

For camera-based measurement systems like the ones Conoptica manufactures, the recording of data is sourced from analyzing video images. The nominal model is used as a guide to locate the actual structures we are looking for within the object we’re measuring.

Let’s see how this works in practice by looking at an example. Imagine a round hole is drilled in a steel plate and we want to measure its diameter. We could use simple vernier calipers, but because we want to be as accurate as possible, we’ll instead use an advanced, camera-based measurement system.

Our measuring device will record several points around the hole (known as “scatter” points). The nominal model will then be applied and fitted against what we’ve recorded according to defined rules (a common method would be to orient the model around a center of gravity for the recorded points, but this may vary).

One this has been done, the measurement system will try to fit the measured points to the shape of the nominal model using a number of mathematically based approaches. The actual shape will, of course, always vary from the model to some extent. It may turn out, in this light, that the hole is not as we thought circular at all but has a sort of quasi-elliptical shape. If that’s the case, the nominal model will be defined as an ellipse, not a circle. Only once the shape has been defined in this way can parameters be calculated. If it turned out that our hole was an ellipse rather than a circle, we would typically be interested in (and want to measure) the maximum and minimum diameters. Put another way, only by being so informed would we know what to measure.

Why it matters

Using a nominal model into which to fit our measured points gives us some advantages. For a start, the measurement result we attain will provide a more robust defense against dirty or damaged objects. Furthermore, it will also make it possible to pre-define a number of derived parameters to be calculated from the same measurement data.

Let’s investigate the dirt issue in more detail because it’s instructive in spelling the advantages out. In industrial conditions, dust, dirt, oil, and grease are commonly present. If the objects you’re measuring are operating in such an environment, the chances that some of them will be dirty when we measure them. So let us look at the hole in the plate again.

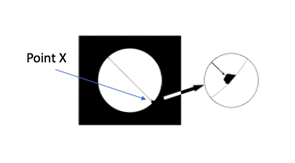

Figure 1: Measuring an object affected by a speck of dirt.

In Figure 1, above, a small speck of dirt is present (you can see this in the zoom to the right). The minimum diameter measurement in this example will choose the diameter that has been affected. Is this the correct way to measure?

The result of the above is what you’d get if you used a measurement system that doesn’t use a nominal model, and so theoretically it is correct. According to your instrument, point X (highlighted in the diagram above) is the minimum diameter of the hole even though it’s not (or is only so due to the presence of dirt). This result, in a nutshell, makes it clear why using a nominal model is so important.

The takeaway here is that using model-based measurement helps to avoid situations like the one above as having a nominal model means the measurement system will try to “fit” the measured points to an expected shape and, thus, will automatically show up variances and problems like that created by the speck of dirt when something strays from the predicted result.

Conclusion

To summarize the importance of model-based measurement, let’s go back to the beginning. Remember that all measurements are precluded by a conceptualization. Without one, it’s impossible to take a measurement because we wouldn’t have the context required to know which dimensions to measure (we might end up trying to measure the length of a circle). In high-end measuring devices like Conoptica’s, this “context” is provided by using a nominal model, the deployment of which enables taken measurements to be understood.

About Conoptica

If you want to learn more about model-based measurement and how they’re used in Conoptica’s measuring devices, please get in touch. Conoptica has been providing high tech camera-based measurement solutions for the metal working industry since the 1993. We make sure that the metal working industry has access to key quantitative data about their products and tools. Conoptica is the market leader for measurement equipment in the wire & cable industry.